HOW TO USE

Always make sure the breaker is connected to a power source which is in the appropriate range as prescribed in specification above.

PREPARATIONS

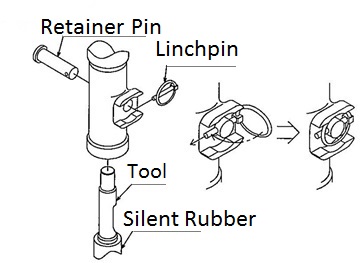

1. Unlock the linchpin and retainer pin to insert the tool.

Turn around the tool (if the tool is hexagon) if it stuck on the half way of the inserting.

2. Set the linchpin and retainer pin.(Refer below)

Make sure the tool is firmly fastened.

3. Make sure there is no dust or dirt inside couplers before connecting breaker to hydraulic power pack. After attaching, lock the couplers.

4. Start the engine on the power pack.

OPERATIONS

5. The breaker and the breaking target should be on a right angle.

Press down the breaker with your weight. Grip the safety lock lever and then control lever.

The machine will start function.(How to unlock Safety Lock Lever)

6. Do not hammer the same place for over 30 seconds.

If the target object does not break within 30 seconds, change the hammering point.

7. Do not blank hammering for over 10 seconds.

8. The effect of low noise weakens when the silent rubber of the tool deteriorate.

Replace silent rubber.

AFTER OPERATIONS

9. After operation, stop the power source.

10. Push the tool to push in the piston.

11. Detach the extension hoses.

12. Attach both couplers on the breakers together.

This is to prevent dust and dirt into couplers and hoses.

13. Remove mud and dirt on breaker thoroughly.

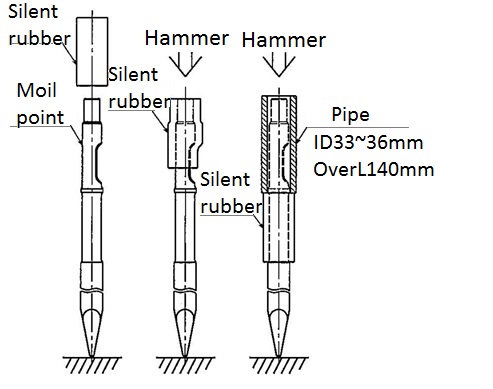

HOW TO REPLACE SILENT RUBBER

1. To remove deterioration silent rubber, take of the rubber by cutting it with a knife.

2. For installation, apply oil to the inner diameter of the silent rubber,

hit the top with a plastic hammer so it would not damage the silent rubber.

Insert until it is aligned with the moil point.

3. Use something like a pipe to insert silent rubber to groove part like below.