1. DAILY INSPECTIONS

Before operation, always check the followings and be sure there are no damages or troubles.

| Inspection Items |

Countermeasures |

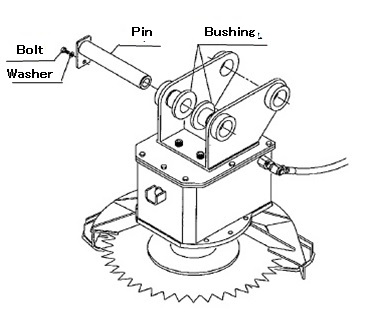

| 1. Looseness of bolts of pin bracket |

When loosened, degrease the bolts and re-tighten with tightening torque of 196N/m applied lock tight No.1342 |

| 2. Looseness of hoses |

When loosened, re-tighten |

| 3. Looseness of bolts for blade cover |

When loosened, re-tighten |

| 4. Leakage of oil from inside of machine |

Repair the machine in our service center. |

| 5. Check the rotation without attaching the blade |

When the rotation is not in center and swung, repair the machine in |

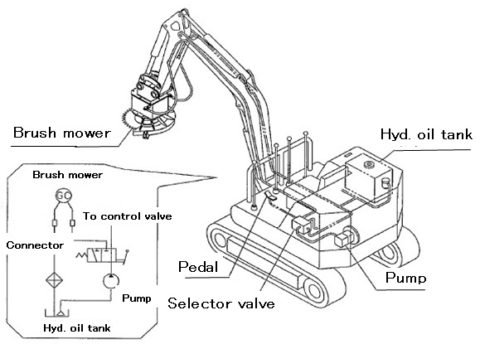

(1) Check the volume and dirt of hydraulic oil in the tank.

The dirt of hydraulic oil may cause the damage of motor and flow divider of GC600.

Replace the oil when it is dirty.

(2) When stored GC600, dismount it from excavator and apply anti-corrosive oil.

Hoses should be stored connected the couplers.

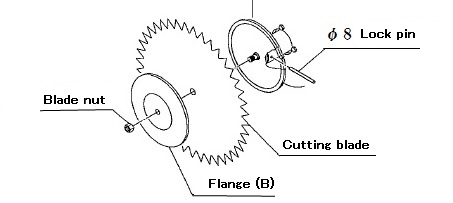

(3) The nut (counter clockwise) for setting the blade should be replaced max after 5 times use.

Don’t use the nut over 5 times. Also, don’t use the nut except genuine one.

Failure to observe this can result the serious personal injuries.

(4) Be sure the tightening torque of the nut of blade.

Tightening torque: 150-180N/m.

2. PERIODICAL INSPECTIONS

Ask your Maruzen dealer for the periodical inspections.

| Inspection Items |

Inspection Cycle |

| Replacement of Oil Tube and O-ring |

Less than 3 years |

| Preplacement of Seals of Hydraulic Motor and O-ring |

Less than 3 years |

| Replacement of O-ring for Flow Divider |

Less than 3 years |

| Replacement of O-ring for Adaptors |

Less than 3 years |