HOW TO USE

OPERATION

Make sure this water pump is being connected to a suitable power source before operating.

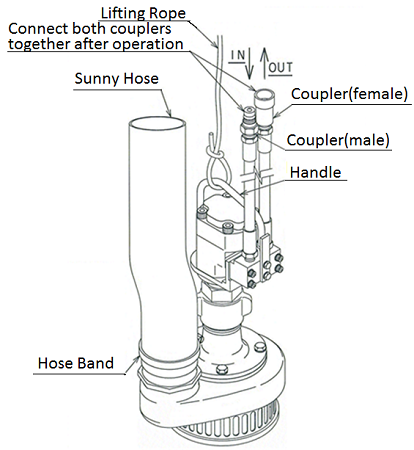

1. Attach sunny hose to the water pump and tighten with hose band to make sure that sunny hose does not being detached from water pump during the operation.

2. Connect water pump and power unit with hydraulic hoses.

(Make sure the male coupler is being connected to IN side)

3. Locate the water pump into water.

Always use ropes to lift or suspend the water pump.

4. Start the power unit.

5. Turn the control lever “ON” on power unit to start pumping water.

AFTER THE OPERATION

1. Turn off the control lever on power unit.

2. Stop the power unit.

3. Lift the water pump with ropes.

(DO NOT pull hydraulic hoses.Fail to follow this instruction may cause the damage to the machine)

4. In order to prevent dirt or dust entering hoses, connect both couplers of hoses on pump after detaching them from extension hoses.

5. Remove sunny hose and clean the pump thoroughly to make sure all the dirt and dust inside has been removed.

Air dry the machine after cleaning.