HOW TO USE

1. Before Starting Engine:

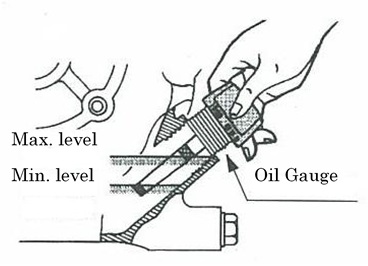

(1) Engine Oil:

Check the engine oil level by oil gauge.

Refill engine oil when the oil is below the min. level.

Recommended engine oil: SAE 10W-30 or equivalent. Capacity: 0.6L

(2) Hydraulic Oil:

Refill hydraulic oil when the oil level is below the oil indication window.

Open the plug on the top of the oil tank,

pour in hydraulic oil till the oil level reach to the middle of the indication window.

Recommended hydraulic oil: ISO VG32 or equivalent. Capacity: 4L

(3) Fuel:

Refill gasoline into the fuel tank.

Capacity: 3.6L

* Wipe out spilled gasoline on machines.

2. Starting Engine:

(1) Attach power unit and equipment (breakers and etc.) with connection hoses before starting engine.

DO NOT start engine without connecting to equipment with hoses.

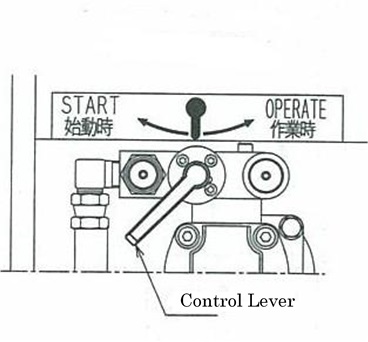

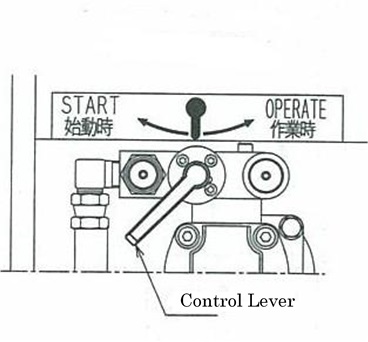

MAKE SURE control lever indicate to “START” position.

(2) Start operation

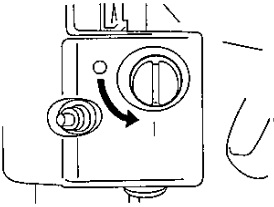

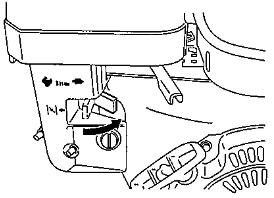

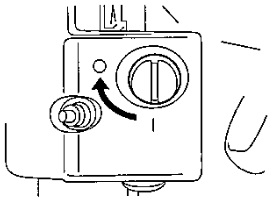

①Open the fuel cock.

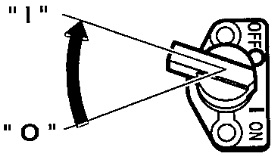

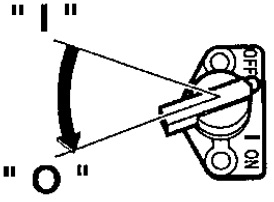

②Turn the switch to “ON”

③Turn the speed control lever from low speed (L) toward to high speed (H) and stop at 1/3 closer to (H) position.

④Close the choke lever.

When to open the choke lever:

・When the weather is cold or when the engine is cold, close the choke lever.

・When the weather is warm or when starting the engine right after stopping,

fully or partially open the choke.

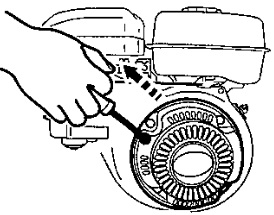

⑤Pull start rope gradually.

DO NOT pull the starting rope rapidly.

After the rope being fully pulled, DO NOT release it from your hand.

Hold the starting rope till it returns to its original position.

⑥After the engine being started, open the choke lever.

Open the choke lever gradually according to the engine’s condition.

Eventually, the choke lever should be fully opened.

・When the weather is cold, engine might stop if you turn the choke lever too rapidly.

3. Operation:

(1) Turn the throttle to high speed (H)

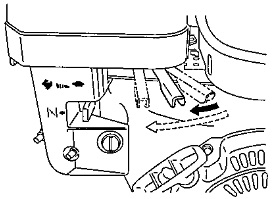

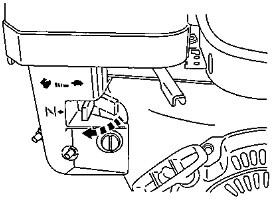

(2) Turn the control lever to the “OPERATE” position.

(Refer to the drawing on the right)

(3) Read through all operating manuals of equipment which you intend to use with this power unit.

(4) When stopping the operation of the equipment (breakers and etc.) ALWAYS turn the engine throttle to the Low Speed (L) side.

This can save energy and reduce the noise level.

4. Stop:

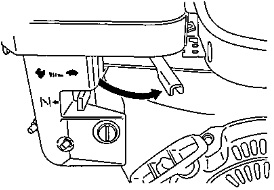

(1) Turn the speed control lever to Low Speed (L) side and run the machine for 1 to 2 minutes.

(2) Turn the switch to “O” Off side.

(3) Turn off the fuel cock.

(4) Detach connection hoses from equipment (breakers and etc.)

Connect couplers on the hoses together.

< CAUTION >

The temperature of the machine goes high while being operated.

Always wear gloves when operating the equipment (breakers and etc.)