HOW TO USE

Be sure that pressure and oil flow of the power source is suitable with specification above.

1. Before Start

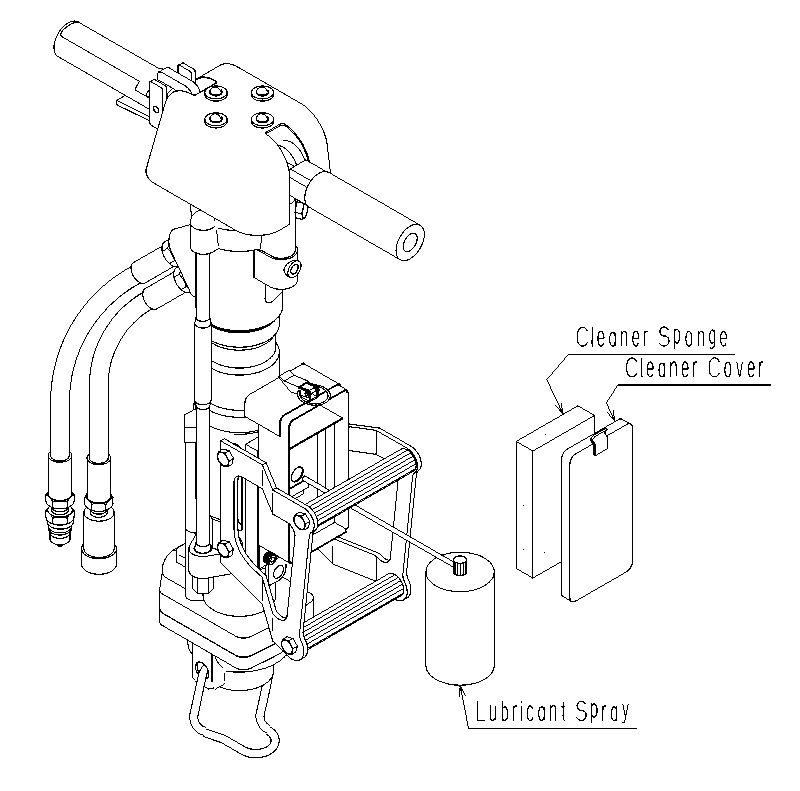

(1)Open the drill stay and insert the drill rod.

Make sure if the drill rod is not too much worn out or exceed usage limit.

NOTE: Ensure that power source and drill is disconnected when inserting the drill rod to prevent unexpected activation.

NOTE: Ensure to use drill rod with shank size 7/8” x 4-1/4” (22x108mm) hex. Do not use other sizes. Ensure the holes of drill rod and bit is not plugged.

(2) Close the drill stay. Make sure the rod(or other tools)is firmly locked.

(3) Make sure there are no dust, mud, or other foreigner substance on couplers when attaching extension hose and power source.(Lock couplers after connection.)

(4) Start the power source and allow hydraulic oil to flow into rock drill.

2. Operation

(1) Drilling

①Place the end of the rod on the place where you intend to drill, press down the rock drill gently, grip the control lever and start drilling.

Rotation direction is clockwise when you look from the top of drill.

(When rotating un-clockwise, please check the hoses are connected correctly.)

②For preventing rock drill to bouncing around while operating, let the end of the rod closed to one of your feet and drill until the rock drill can be stably operated.

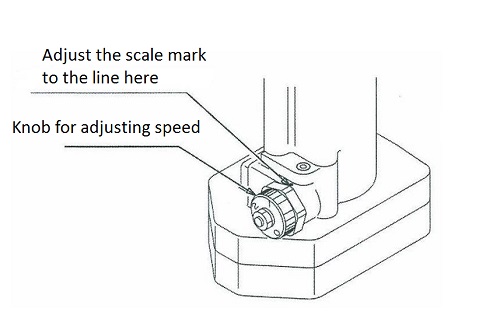

③Adjust the rotation speed according to the type of the rock.

| MODE | Rotation per minutes | Application |

| 1 | 240 rpm | Hard Rock |

| 2 | 350 rpm | Medium to Hard Rock |

| 3 | 675 rpm | Soft Rock |

*Rotation per minute above is rough standard. Please choose the mode depending on situation.

(2) Breaking

① Use fluted moil point to have air escape.

② Open drill stay and insert moil point.

③ Close the drill stay. Make sure the moil point has been fastened firmly.

④ Adjust the knob to “0″ position.

3. After the Operation

(1) After the operation, stop the power source.

(2) Detach the connection hoses.

(3) Make sure all the couplers on standard hoses(attached to rock drill)and connection hoses are attached to each other to prevent dirt and etc. entering.

(4) Open the drill stay and remove moil point or tool.

(5) Clean all dirt, mud, and etc. on the rock drill.