HOW TO USE

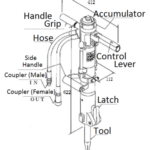

When connecting this breaker to a power source other than Maruzen UH070 power unit, make sure the power source you intend to use is within the range (oil flow, pressure etc.) prescribed above.

PREPARATION

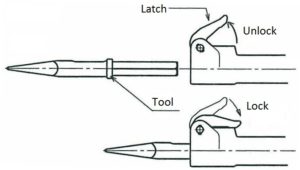

1. Unlock the latch on the breaker and insert tool (moil point etc.)

Turn around the tool (Hexagon tool) if it stuck on the half way of inserting.

2. Lock the latch. Make sure the tool is firmly fastened.

3. Make sure there is no dust or dirt inside couplers before connecting breaker to the hydraulic power pack.

4. Active the power source.

(Start the engine on the power pack)

OPERATION

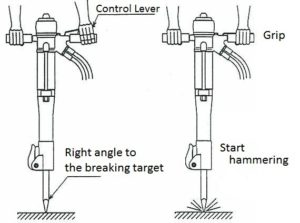

5. The breaker and the breaking target should be at a right angle.

Press down the breaker with your body weight.

Grip the control lever and start hammering.

6. Do not hammer the same place for over 30 seconds.

If the target object does not break within 30 seconds, change the hammering point.

7. Do not blank hammering for over 10 seconds.

AFTER OPERATION

8. Stop the power pack when the job has completed.

9. Push up the tool so the piston return to the position.

10. Detach the extension hoses.

11. Attach both couplers which are on the breaker together to prevent dust and dirt entering.

12. Unlock Latch, remove the tool from the main body.

13. Remove mud and dirt on breaker thoroughly.