HOW TO USE

Check and confirm if the oil flow and pressure of power source are suitable with the specifications of this tool. Wear appropriate safety equipment when operating this tool.

PREPARATION

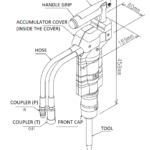

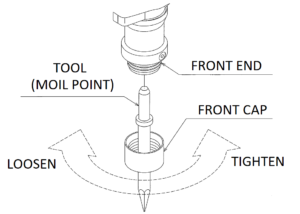

1. Insert the tool into front end and screw front cap with hand until it is tighten.

2. Make sure that there are no dirt or dust on the couplers before connecting the tool and power source with extension hoses.

3. Start power source and open the oil circuit.

4. Use optional MB48Z034A ECCENTRIC FRONT CAP when using special tools such as cutters.

OPERATION

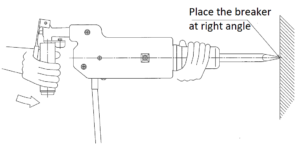

1. Place the breaker and the breaking object on a right angle and press down the breaker. Grip the control lever to start hammering.

2. Do not hammer the same place for over 30 seconds. If the target object does not break within 30 seconds, change the hammering point.

3. Do not make a blank hammering for over 10 seconds.

AFTER OPERATION

1. After operation, stop the power source.

2. Push up the tool to make the piston return to the original position.

3. Detach the extension hoses.

4. Connect both couplers on the breaker to prevent dust and dirt entering.

5. Remove mud and dirt on the breaker.