HOW TO USE

Make sure this post driver is being connected to a suitable power source before operating.

Preparation

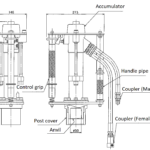

1. Connect the post driver with hydraulic power source with extension hoses

2. Attaching ∅4mm(or more) lifting wires on top plate to lift the pile driver. (Refer to the Illustration on the right)

3. Set pile or pole which you intend to drive vertically to the ground.

Set the pile guide on the top of the pile or pole which you intend to drive.

Operation

4. Start the power unit or other power source.

5. Slightly releasing lifting wires in order to start operating.

6. Hold on handle grip and control grip with both hands.

To start operating, pressure down the pile driver and control grip.

7. Release control grip when intend to stop the machine.

After the operation

8. Stop the power unit or power source.

9. Remove the extension hoses.

10. For preventing dust, dirt entering the extension hoses, attach both sides of the couplers on extension hose to each other.

11. Clean and wide out dirt and dust on pile driver.